The original Radioshuttle®

Fast, reliable and safe technology with future DNA.

Efficient in all

temperature zones

Quick and easy storage in freezing cold to warm environments

Complex yet so

easy to operate

Sixth generation of successful progress

Increased productivity

Moves pallets at over twice the speed

A reliable business companion

Designed, engineered and manufactured with unparalleled durability by Radioshuttle®

Fully automated

Radioshuttle® is prepared to handle a fully automated warehouse with driverless trucks and cranes, having your staff focusing on other things. Your investment is, in order words, ready for Industry 4.0 when you are.

Works in all temperature zones

No matter if you have a freezer or a cold storage, Radioshuttle® can operate in all temperature zones. With experience from temperatures from -30 to +40 degrees Celcius, anything is possible.

Features

With a complete system you can operate with confidence: Confidence the day you start using the system and continued confidence during the decades Radioshuttle® is in use. This is the result of 30 years of evolution and continuous improvement.

Battery technology

Every Radioshuttle® power supply has been designed to exceed a full shift of operation between battery changes. The choice of battery technology is determined by the requirements of the application

Pedestrian protection system

Mounted on the lower middle face of the Radioshuttle®, the pedestrian protection scanner scans a predefined field for anything that may come into contact with the shuttle and load. If it detects an obstacle, the shuttle will decelerate and stop at a safe distance.

Our shuttle complies with the latest CE norm (EN 13849-1:2016), which requires a pedestrian protection like scanner. This allows its top speed to be 3X as fast than if it weren’t certified.

The shuttle provides ultimate safety so you can use its potential at 100%.

Communication information display (CID)

Large, clear and easily readable from the operator’s lift truck, the CID gives direct feedback important for your operation:

- The function the shuttle is executing

- Immediate shuttle status control including service codes to make the operation safer and more productive

- A lane’s capacity, total cycles, etc.

All these features are standard for Radioshuttle®.

Radioshuttle® capacity

Radioshuttle® is designed to carry a maximum 1800 kg capacity. The rugged drive and lift system will run for many trouble free years in an industrial environment.

Light/sound warning system

With a total of six predefined lights and an internal speaker, communicating with the operator is a snap. The operator is never left guessing what the status is of a Radioshuttle® in operation or at rest. This gives you a faster, safer and more friendly operation.

Remote operation

You can choose one of two options to control your shuttle:

1) A truck-mounted, ‘one touch operation’ remote control.

2) A Warehouse Management/Control HMI screen with a customized menu operating on your existing Wi-Fi network.

Speed

The Radioshuttle® top speed with and without load are the fastest in the industry – but that is only half the story.

Radioshuttle® leads the world with the shortest time from executing a command to the completion of each command. In other words, Radioshuttle® will handle more pallets in shorter time.

Fleet management compatible

Looking for a system to help manage your industrial equipment? Radioshuttle® is compatible with several fleet management tools. It can easily be incorporated into your fleet management program for data reporting and complete warehouse optimization.

LED light beams

Four LED position aiming lights guide the operator’s forks to the correct position to carry the shuttle. These high strength light beams are a critical part of the overall transportation system.

The beams help to position forks faster and safer and reduce risk of potential damage.

Anti-slip surface

Our unique Anti-slip surface keeps the shuttle firmly in position during transport and considerably reduces risk of potential damage.

We also have changeable anti-slip surface on shuttle’s lifting pads which holds the load firmly in position and gives you a faster, safer and trouble free load handling.

Fork containment channel

The center channel of the shuttle protrudes below the chassis to create a secure right-and-left barrier to movement. This helps to position forks for transport faster and easier and reduces risk of potential damage.

“Radioshuttle® really helps us to improve efficiency and to create more storage space.”

Radioshuttle®

Operate with confidence

Each shuttle is equipped with features like warning lights, audio signals, bright and clear display systems, etc. This is the result of 30 years of evolution and continuous improvement.

We have a significant Research and Development program to improve the performance and deliver the most robust shuttle available.

With a complete system you can operate with confidence: Confidence the day you start using the system and continued confidence during the decades Radioshuttle® is in use.

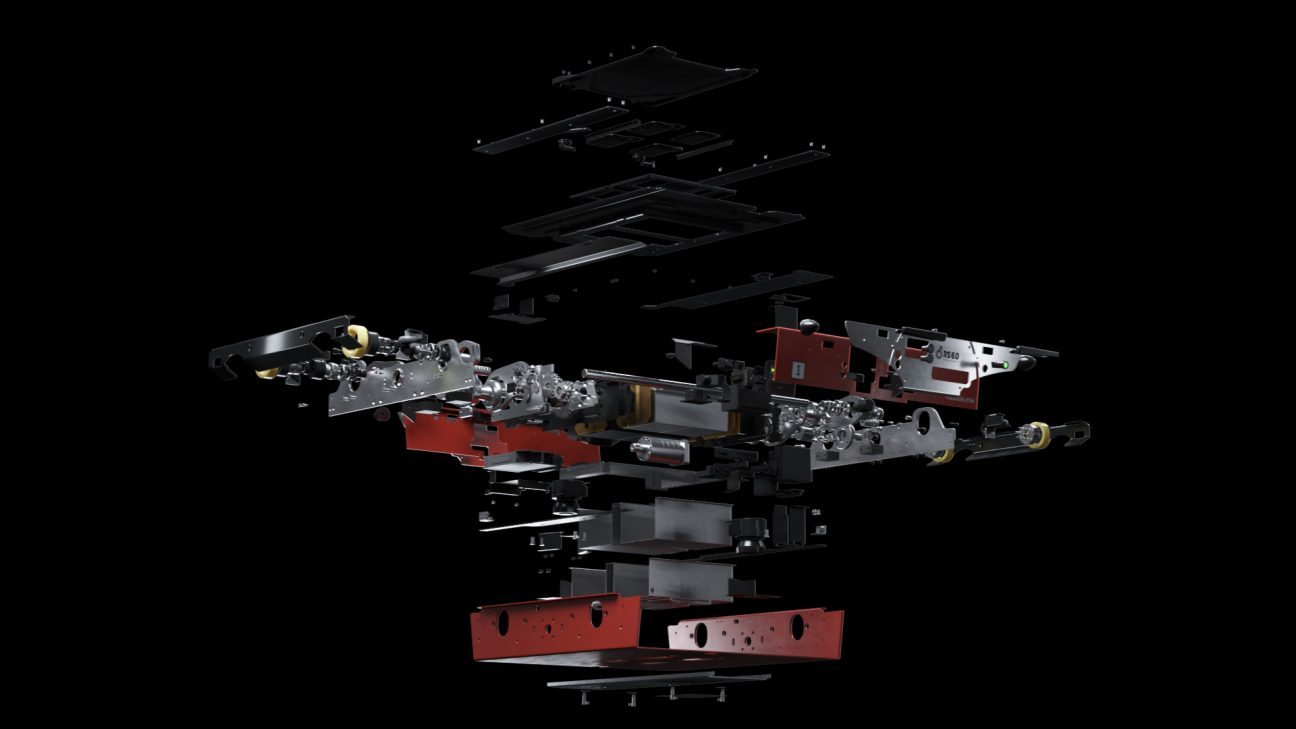

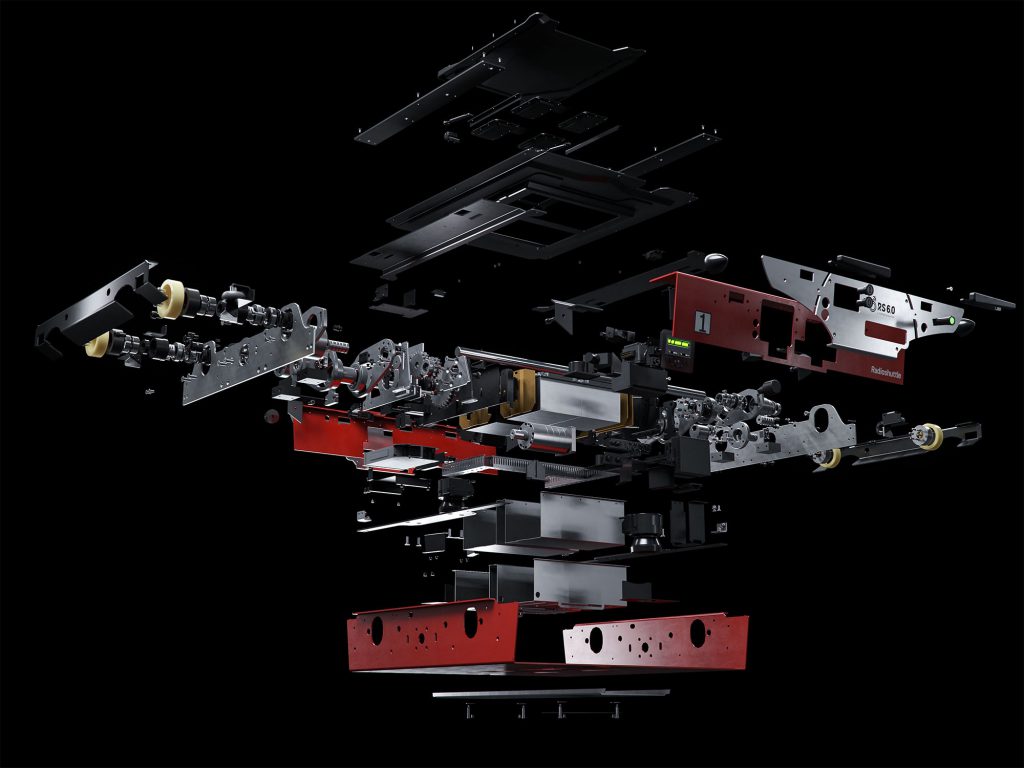

Components

Radioshuttle® configurations – It’s your choice

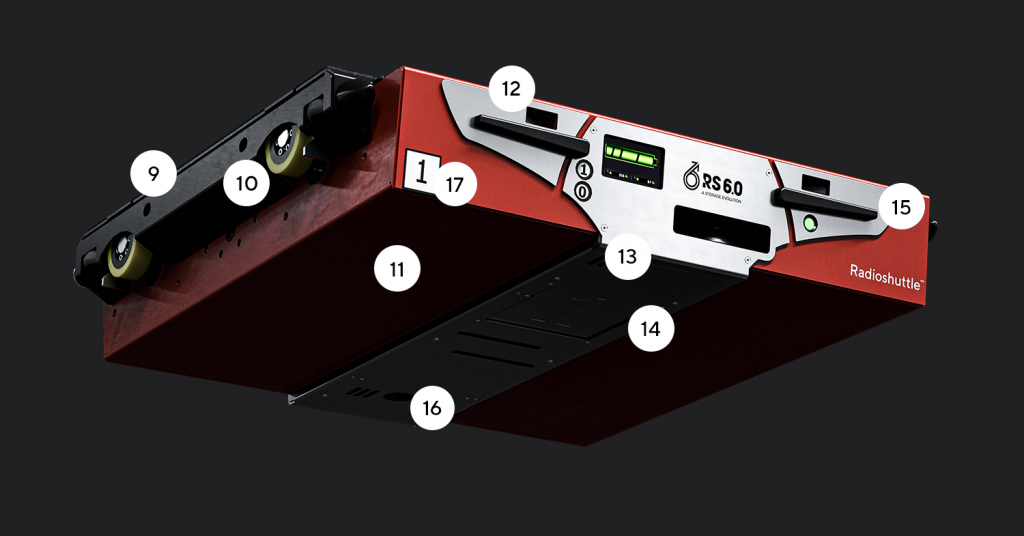

The shuttle

Each shuttle is equipped with features like warning lights, audio signals, bright and clear display systems, etc. This is the result of 30 years of evolution and continuous improvement.

- Side guidance

- Sweeper arm

- Bumper

- Battery compartment

- Communication information display

- Safety scanner

- Upward sensor

- Status lamp

- Side sensor

- Wheel

- Grip surface

- Forward sensor

- Directional travel lights

- LED light beam

- Fork bumper

- RFID reader

- Inclination sensor

FlipRemote control

To control the operation of Radioshuttle®, we have engineered a simple and straightforward remote control device.

The operation of the remote is so simple and so straightforward that very little training is required for an operator to become fluent in its use.

It is designed to work in ambient and, of course, frozen temperatures… and will even work when the operator wears thick insulated gloves.

Simple and straightforward

Radioshuttle® Connect

Send all commands of the remote control. Receive real time information back.

Radioshuttle® Connect enables two-way communication between the shuttle and a device of your choice – the only thing you need is a web browser. It acts as a merger between the handheld remote control and the information display of the shuttle.

Charging station

Radioshuttle® charging station helps you to extend battery lifetime and keep an ergonomic and safe environment. The station anti-slip top surface is also practical – often used as a small work table. The charging station gives you the opportunity to keep proper order on the charging of batteries.

In each charging station there is space for two sets of batteries (four individual battery cassettes). The battery cassettes are placed in an easily extendable drawer equipped with automatic power engagement. When the drawer is closed the charging starts automatically.

There is a display on the station clearly showing the status of the batteries.

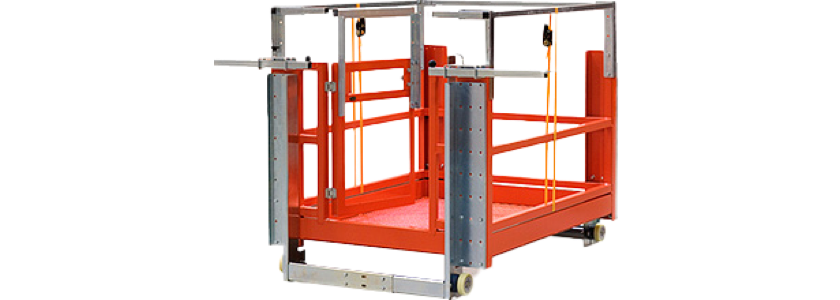

Work platform

For the times when maintenance is required to enter the rack structure, we have designed the Radioshuttle® work platform.

This ingenious vehicle can be manoeuvred into place with standard lift trucks – and the operator can carry out maintenance functions in both a safe and secure environment.

WiFi (optional)

The shuttle can be connected to a WiFi network to allow communication between the shuttle and the server. This help you to operate through your WMS and other tools installed in your WMS structure.

WiFi also allows the shuttle to be connected to a fully automated system.

Parking station (optional)

Radioshuttle® parking station has been designed to accommodate the shuttles when they are not in use. In this case, users can simply store them away from the system.

For example, in a warehouse that only operates 16 hours/day, the shuttle can be parked in the rack and charged without removing the batteries.

Unparalleled durability and world class performance designed into one system

All Radioshuttle® components have been designed, engineered and manufactured by one company from the ground up to function as one system. A sophisticated system, yet easy to use.

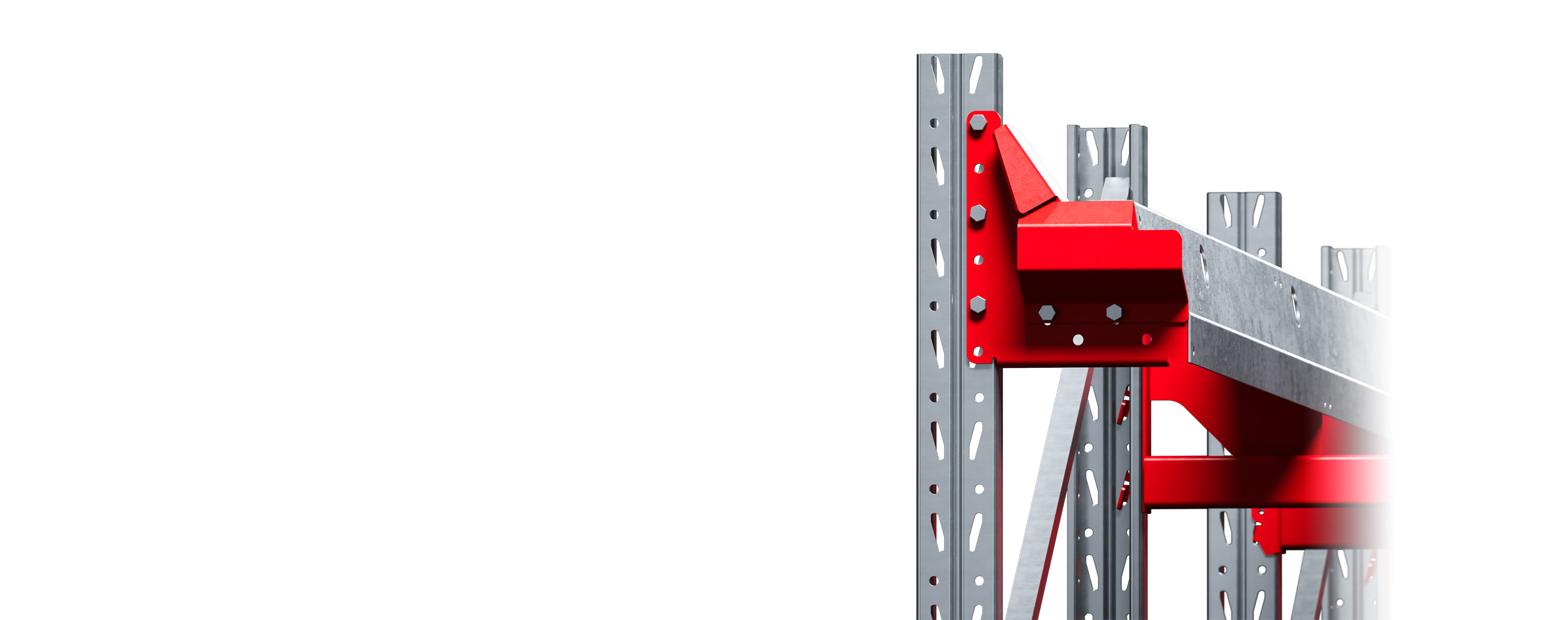

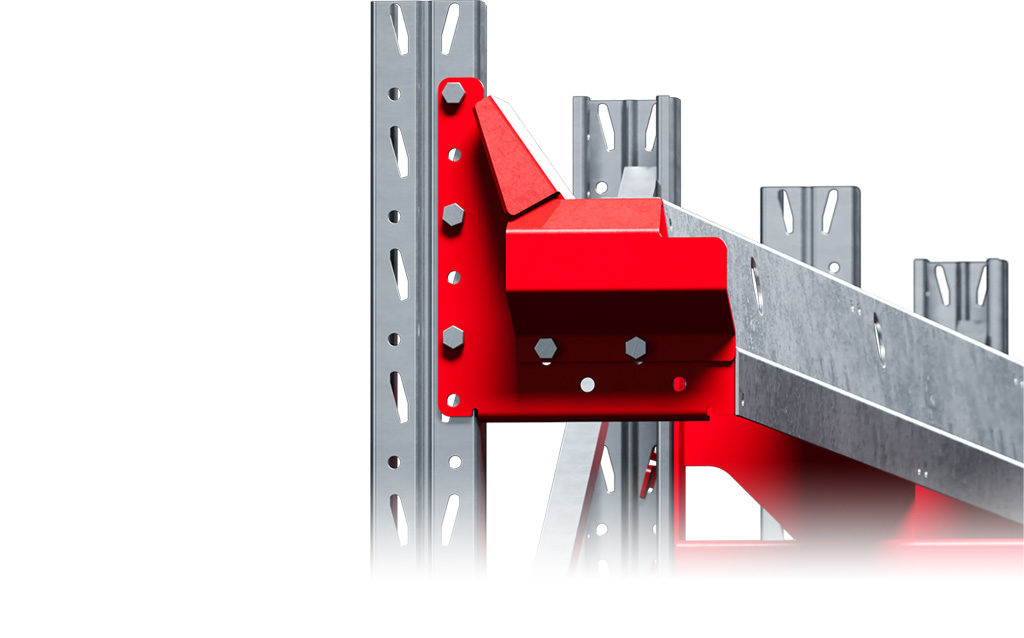

Explore the structure